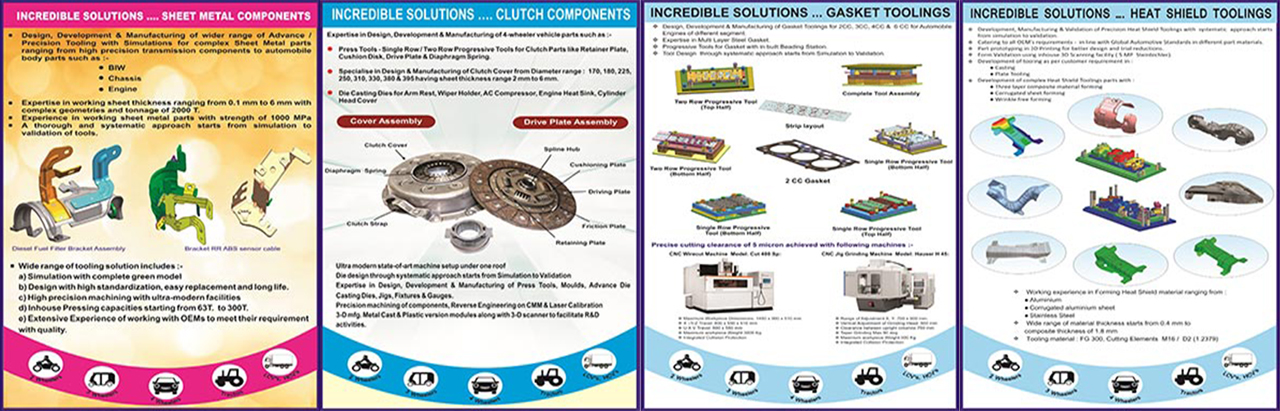

Quality Assurance

“QUALITY IS A WAY OF LIFE”

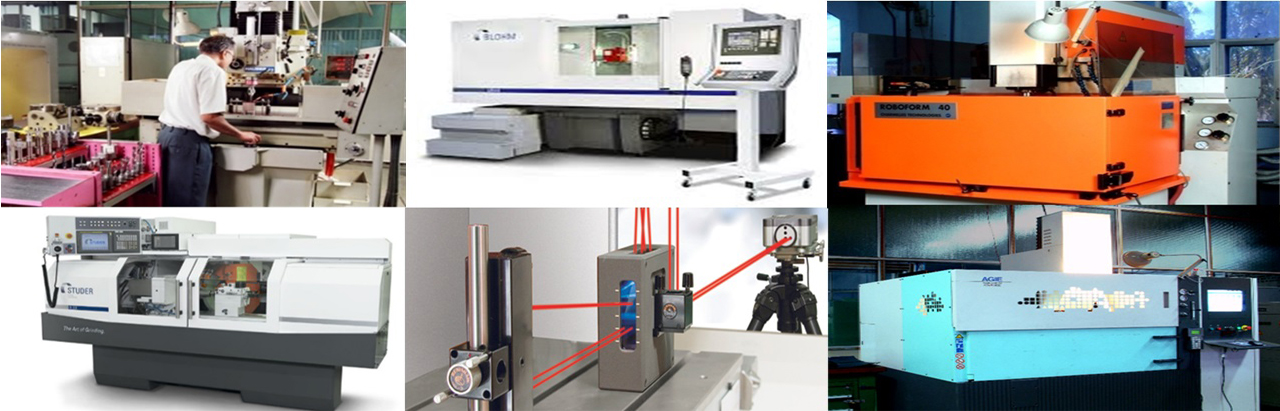

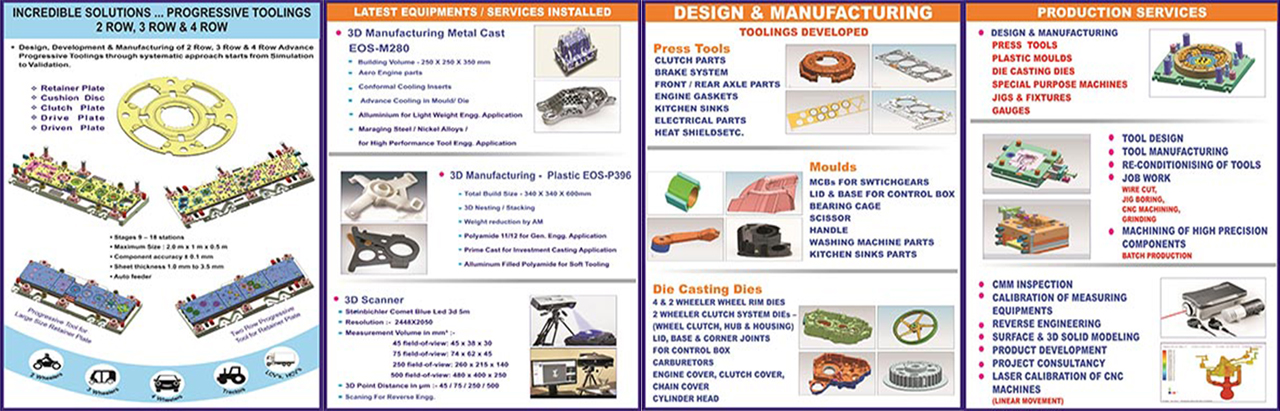

IGTR Aurangabad strongly believes in Total Quality Management (TQM) & adheres to its principles. This belief is evident in the procedures adopted for checking components during & after manufacture. High Precision equipment like CNC Coordinate Measuring Machine, Electronic Height Master, profile Projector & Tool Makers Microscope ensure thorough checking of the components.

- Carl-Zeiss – Prismo

- Brown & Sharp- Hexagon Globel

- Baty Profile projector

- Mitutoyo Tool makers microscope

- Mitutoyo Electronic Height Master

A full fledged standards room has also offers calibration services as per ISO 9001 requirements & the lab is in the final stages of acquiring NABL accredation for calibration services.

QUALITY ASSURANCE CARRIES OUT

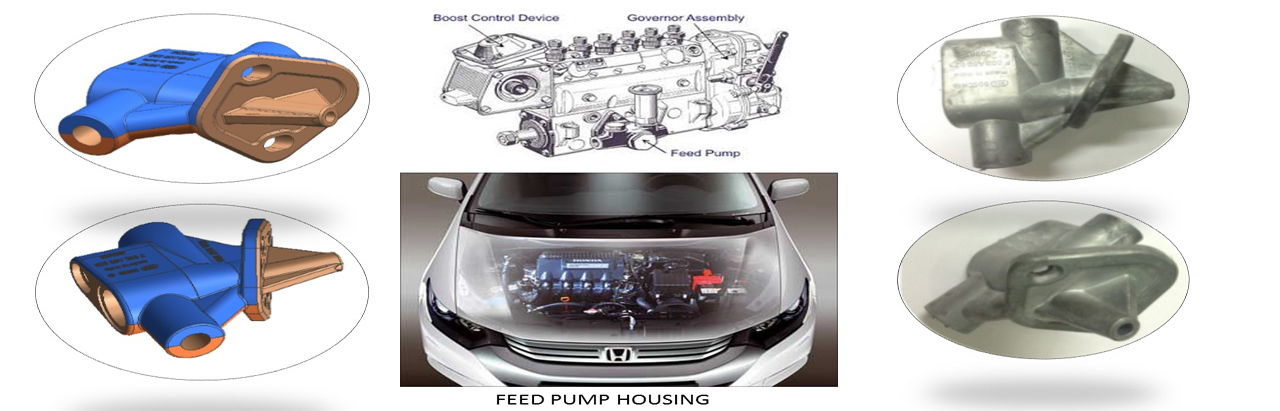

- Product Conformance & Inspection

- Calibration Of Measuring Equipments

- Scanning For Reverse Engineering

INFRASTRUCTURE IN THE QA INCLUDES:

| CNC CO-ORDINATE MEASURING MACHINE |

CARL – ZEISS PRISMO 5, VAST |

| Hexagaon Metrology Global Performance 05x07x05 |

|

| LINEAR HEIGHT MASTER (ELECTRONIC) |

MITUTOYO |

| TOOL MAKER’S MICROSCOPE |

CARL – ZEISS ( 10 X, 30 X ) |

| PROFILE PROJECTOR |

BATTY (10X, 20X, 50X) |

| SURFACE FINISH TESTER |

HOMMEL |

| PRECISION COMPARATOR STAND |

SYLVAC |

| SLIP GAUGES (CARBIDE) | KOLB + BAUMAN |

Apart from above, other instruments for calibration like Caliper checker, Muchecker & Master Gauges, Optical Flat etc. are also available.